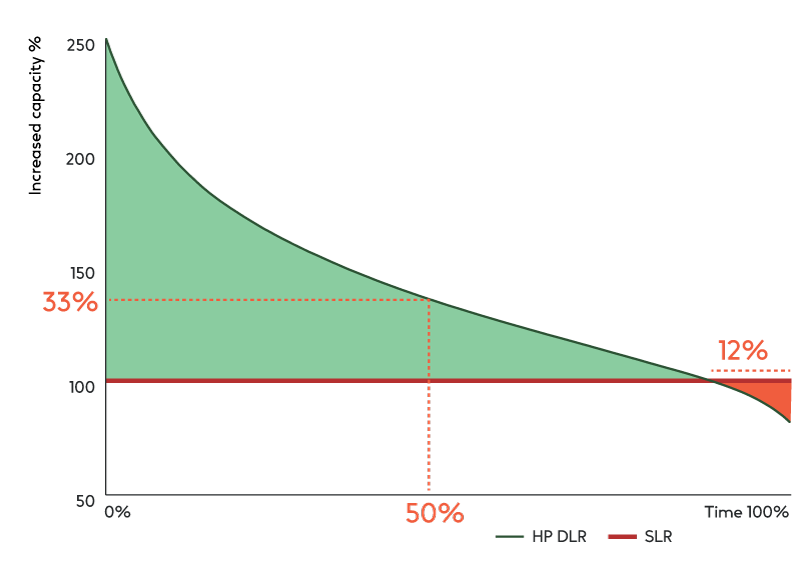

We have gathered data from our neurons across six European countries, and the data confirms a significant potential for increased capacity. Lines instrumented with Heimdall Power neurons can increase available capacity with 33 per cent or more over half the year. The median value for increased capacity is 41 per cent.

Max power and max control

Grid companies across Europe are benefiting from Heimdall Power´s real-time visualization of thermal capacity, which enable precise dynamic line ratings (DLR). We use the fact that capacity in overhead lines depends on temperature, which varies throughout the year and throughout the day with solar and wind conditions. With real-time information about available capacity, grid companies can plan and operate proactively for max power and max control and utilize the potential of the grid.

Figure 1 shows additional available capacity in per cent over time compared to static line rating (SLR) which is set to a constant of 100 per cent. Data for SLR is defined by the respective grid companies, and it varies how conservative these values are. Some grid companies already vary the line rating with e.g. different values for summer and winter. We have examples of the potential capacity being a multiple of the actual use. The plot is based on data across a wide range of our projects, with the extreme values removed. The green area above the SLR curve shows the potential additional capacity.

In short periods the capacity

exceeds 200 per cent, whereas:

We call this the power of knowing.

With the Heimdall Power neuron grid companies get precise real-time insight into available thermal capacity on their lines. This means that the grid company can utilize the full potential and connect new consumption or new generation faster, operate the grid more dynamically and safely, save money on re-dispatching as well as limit infrastructure investments.

Real-time information about situations when the thermal capacity is below SLR can be critically important for operating the grid within safe limits.

Basics about DLR

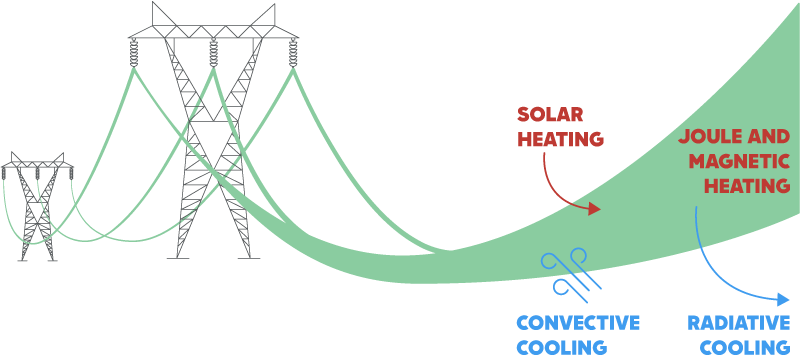

Most grid companies today operate their lines with SLR (static line rating), typically rated for warm summer days. Most of the year, however, the ambient temperature is below that, meaning that the capacity of the line is higher. DLR (dynamic line rating) uses the fact that capacity varies with ambient temperatures and weather conditions. Whereas wind and rain cool the lines, the sun heats them up. To utilize the capacity fully, it is crucial to know the real thermal limit.

Figure 2. The capacity on a power line is limited by temperature

Heimdall Power DLR is based on a method formulated by CIGRE and improves on it by adding real-time measurements from our Heimdall Power neuron. The combination of weather data from renowned sources with sophisticated measurements means that we capture situations where nearby lines differ in thermal capacity due to local geography and features of the immediate surroundings. When instrumenting the lines, Heimdall Power takes these local environmental elements into careful consideration to create the best possible and most reliable DLR.